Probably the oldest tool known to mankind dating back over 2 million years, the venerable hammer has proven that it has staying power It is arguably the most important and basic tool used on a daily basis

Although the materials used in the construction of a hammer have evolved over time, the basic design has not changed a whole heck of a lot. Function, durability and ease of use are the main qualities to consider when choosing a hammer.

Anatomy of a Hammer

Head: Hammer heads are commonly made of forged, heat-treated, high-grade steel. Mallets (technically part of the hammer family) have wooden, rubber or plastic heads.

Striking Face: These range from the smooth face most often found in multipurpose claw hammers, to the milled/checkered face of a framer hammer which grips the nail head and reduces glancing blows. The double-faced dead blow (one face steel, the other rubber) and the massive hit-the-side-of-a-barn face of an engineer hammer or sledge hammer are other face variations.

Claw: Claw hammers are named after the two narrowing “claws” of steel opposite the striking face. The slot between these two claws looks like a thing “v” and is used to grip and pull nails. The two common types of nail hammers both have claws, but in different configurations. Curved claw hammers allow you to pull nails using an easy rocking motion, as the curve acts as a fulcrum. Straight claw hammers, commonly called “rip hammers”, are designed to rip apart nailed structures.

Handle: The stiffer the handle material, the more the force of your blow will be delivered directly to its target. However, more flexible materials absorb shock and thus reduce stress on the user’s hand, wrist and arm. Most folks who hammer a lot prefer wooden (usually select hickory) handles for their superior shock absorption. Stiffer handles such as fiberglass, steel or graphite, are commonly jacketed with a cushion to absorb some of the shock.

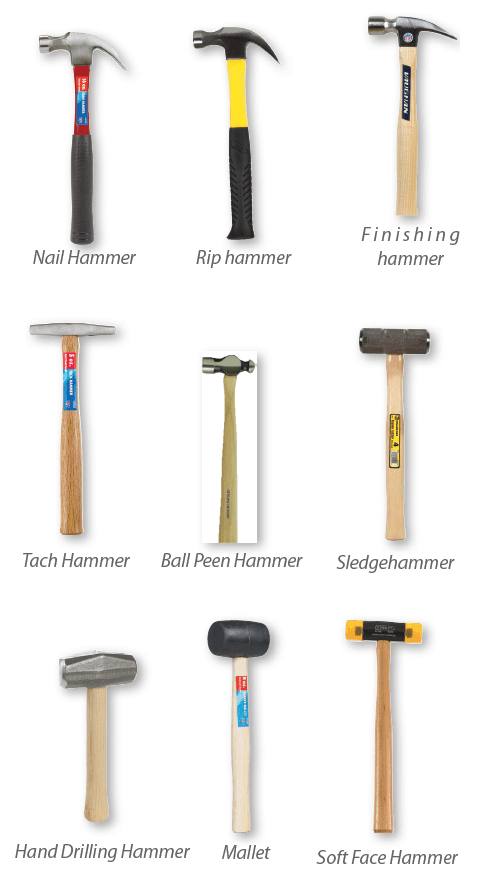

Hammer Types

Hammers come in many different shapes and forms. Holland offers a variety of all of these styles of hammers:

Nail Hammer: Used for general carpentry, household chores and nail pulling; should be used only with non-hardened, common or finishing nails. Curved claw offers leverage in removing nails and can also cradle a 2×4.

Rip Hammer: Used mainly by professionals for ripping apart wooden components and demolition work. Available with milled or waffled faces to grip the nail head and reduce the effect of glancing blows and flying nails.

Finishing Hammer: Used for general carpentry, finishing and cabinet making; smooth striking face so errant strikes don’t leave marks on wood.

Tack Hammer: Used for furniture upholstery and to drive small nails and tacks. Round face is designed to pick up nails and tacks, while the narrow square head is used to drive them. Often comes with a magnetized head.

Ball Peen Hammer: Used with cold chisels for riveting, center punching and forming unhardened metal work. Designed with a regular striking face on one end and rounded or half ball on opposite end instead of a claw.

Sledgehammer: Used for jobs where great force is required such as breaking up concrete or driving heavy spikes. Double-face sledgehammers feature two identical faces; single-face sledgehammers have one flat face for striking and one wedge-shaped face for splitting wood.

Hand Drilling Hammer: Has short handles and is used for pounding hardened nails into concrete or for using with tools that drive nails and pins into concrete or brick.

Mallet: Has rubber, plastic, wooden or rawhide head and is used to drive chisels or hammer joints together. Used where a metal hammer might damage a surface and available in a variety of shapes and sizes for specific tasks.

Soft-Face Hammer: Used for assembling furniture, setting dowels and wood projects that require non-marring blows. Most feature a soft and hard replaceable head.

Bricklayer’s Hammer: Used for setting or splitting bricks, and chipping mortar from bricks. Features a curved, chisel-like pick and a small, square striking surface.

Shingler’s Hammer: Drives roofing nails, assures proper shingle spacing, and trims composition and fiberglass shingles.

Drywall Hammer: Used to score, sheet and set nails for drywall work. Features a scored head and a notched blade instead of a claw; the notch in the blade removes exposed nails.

Basic Hammer Wielding

- Hold the hammer firmly, as far away from the head as you can hold it and still have a good grip.

- For full driving power and to protect your wrists from injury, swing the hammer from your elbow.

- Keep your eye on the target while swinging and strike the target squarely.

- For safety, wear eye protection and avoid glancing blows.

When selecting a hammer, first decide what kind of hammer your job requires and the handle type. Consider if the hammer if the right weight for you, how is the balance between the handle and the head and how the handle itself feels in your hand. These factors are not just about the pleasure of using a well-designed hammer….if you plan to use it for hours at a time, good design will reduce fatigue and minimize strain.